Ceramic atomizing core is one of the commonly used types of electronic cigarette atomizing core. Its common preparation processes are mixing, refining, making billet and sintering forming. Among them, the process of making the billet body has dry pressing, wet pressing, injection molding, etc., if the preliminary powder preparation is very fine, the liquidity will be poor, it can not be very good to fill the mold, resulting in the billet body defects, ultimately affecting the performance of sintering molding.

Therefore, ceramic powder after refining, there is usually a granulation process, some processes called it feeding, today we will understand the ceramic atomized core powder commonly used four granulation methods, of which spray granulation method is the most common application.

Granulation is by adding a certain amount of plasticizer in the fine powder, made into a larger size, with a certain degree of false particle gradation and good mobility of the sphere. The mass of this sphere, called a pellet, can significantly affect subsequent molding and sintering. The mass of a lump can be characterized by its packing density and sphericity.

Common granulation methods are as follows:

1. Spray granulation method

Spray granulation method is to mix the billet and plasticizer into a slurry with a certain solid content, and then spray the slurry into the granulating tower for atomization, you can get good liquidity spherical particles. The high yield of this method is suitable for industrial production.

In production, spray granulation can avoid the reagglomeration or settlement of each component in the slurry, so as to keep the slurry uniform; At the same time, the slurry is atomized evenly, and the spherical particles with uniform particle size distribution and good fluidity can be obtained. Such particles have excellent forming and sintering properties, contributing to the final production of high density, high bending strength sintered body.

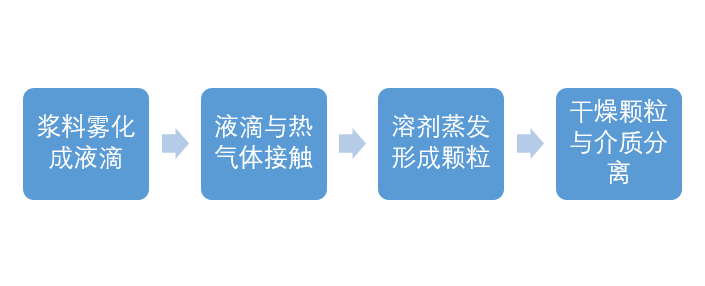

The process of spray granulation includes four parts: slurry atomization into liquid droplets, contact between liquid droplets and hot gas, solvent evaporation into particles, dry particles and medium separation. The first three parts have great influence on the properties of granulated powders. Atomization is to make the slurry form small droplets to increase the specific surface area of the slurry. The mixing process of droplet and hot gas is mainly affected by the flow mode of gas in the drying chamber. After entering the drying chamber, the evaporation rate of the droplet will quickly increase to the maximum. After maintaining this speed for a period of time, it will start to slow down. At this time, the temperature of the droplet will increase, and a solid shell layer will be formed on the surface.

Taking the spray granulation of silicon nitride ceramic powder as an example, centrifugal or pressure spray granulation equipment is usually used to carry out mixing while granulating the mixed SI3N4 slurry, so as to make the SI3N4 powder evenly distributed, so as to improve the sphericity of SI3N4 particles and the fluidity of powder, and improve the particle size distribution of powder. The factors such as temperature, pressure, feeding speed, stirring time and binder type during spray granulation have important effects on particle size and dispersion of si3N4 powder after granulation.

However, the particle morphology of spray granulation is not easy to control, and it is easy to appear hollow, surface pits and other defects. In addition, the powder obtained by spray granulation usually needs to be burned of organic matter, so as to ensure that organic matter is completely excluded so as not to affect the sintering performance of silicon nitride ceramics. Therefore, it is very important to formulate a reasonable gel discharge system and accurately control the gel discharge process.

2. General granulation method

This method is directly in the powder to add plasticizer, after mixing, sifting to get aggregates. The advantage of the general granulation method is easy to operate, but the problem is that the quality of the aggregates is poor, the size of the sphere is different, the sphere is not good.

3, pressure granulation method

Dry press granulation

Dry press granulation refers to the process of forming powder through a mold, then crushing and spheroidizing. The specific steps of dry pressing granulation are: prepressing conveying → rolling forming → crushing granulation. Dry press granulation has the advantages of high granulation efficiency and low production cost. In particular, compared with some granulation methods, such as spray granulation, the binder content required for dry press granulation is very low, which can reduce the problems of low sintering density and many pores caused by the binder.

Cold isostatic pressure granulation

Cold isostatic pressure granulation method is similar to dry pressure granulation method, the same is the powder under a certain pressure molding, then crushing and pelletizing method. The difference is that the ceramic powder is placed in a specific mold and then placed in a cold isostatic pressing device. Cold isostatic pressure takes advantage of the incompressibility of the liquid medium and the characteristics of uniform pressure transfer, which can realize uniform pressure on the sample from all directions to ensure that the pressure of the powder in all directions is uniform and the size is unchanged. The powder is pressed into billet by cold isostatic pressing process, and then crushed by crusher and screened to complete the granulation process.

The advantage of pressure granulation is that the volume density of the pellets is large, which is conducive to improving the density of the billet. The content of plasticizer and other organic matter is less, and the post-treatment is simple; Simple equipment and process; The disadvantage of pressurized granulation is that after crushing, the shape of aggregates is difficult to control, it is generally difficult to be ideal spherical, and there are noise and dust problems, there are adverse effects on the health of operators and production line environment.

4. Freeze-drying method

The method is to spray a metallic salt solution into an organic liquid, which freezes immediately. Then put the frozen substance in low temperature and low pressure environment to sublimate it, dehydration after thermal decomposition, and finally get the required powder. The particles obtained by this method have uniform composition and good forming and sintering properties. But this method is not suitable for industrial mass production, and is used for laboratory granulation.